Leakage detection by professionals

Installing underground pipes and fittings of a drinking water network system generates significant costs for the utilities. Leaks on pipe networks waste precious resources, with the water losses requiring substantial additional financial resources for water purification purposes and for the operation of oversized network structure (pumps, pipes, reservoirs, etc.). Already minor leaks can cause massive financial losses. Therefore, any damage on a pipe network has to be detected and remedied as quickly as possible.

In general, the leakage-borne noise is used to locate a leakage on a pipe. As soon as a liquid escapes a pipe at a damaged spot, shock waves are generated which travel along the water column in both directions in a sinusoidal way. Wherever these shock waves collide with the pipe material, the pipe material is stimulated to vibrate. These mechanical vibrations are called structure-borne sound waves. The farther the waves travel, the less intensive they become. And finally, there is a point where the shock waves do no longer make the pipe material vibrate and thus do no longer generate any noise. This, of course, strongly depends on the kind of soil, its compaction level, the pipe material, the operation pressure, and some other factors.

Leakage detection method

In general, leakage detection activities are separated into zone measurement, leakage pre-locating, and pinpointing. We at F.A.S.T. GmbH offer all three types of leakage detection from one source.

Zone measurement allows quantifying a leak by measuring the zero-consumption status at night (2:00 – 4:00am) thus identifying those areas hosting the biggest leaks. Natural zone limiters are applied to monitor the feeding quantities through firmly installed, immobile meters in basins and at pump stations. If immobile meters cannot be installed in a section or zone, mobile flow-rate meters are applied to measure the flow of fluid.

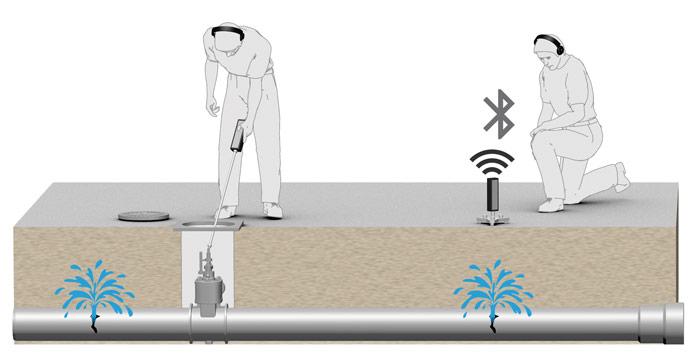

Pre-locating means roughly localizing leaks by systematically listening to pipe network contact points which are directly accessible such as hydrants or valves. The principle is relatively simple: more intensive noise = leak is closer, less intensive noise = leak is farther away. This principle allows narrowing a leak to a certain section between two contact points. The accuracy achieved is usually not sufficient to start excavating. Therefore, subsequent pinpointing is recommended.

Pinpointing. The area which has already been pre-selected through correlator, testrod microphone, and noise logger activities is now listened to with an electro-acoustic listening device in order to pinpoint the exact leakage spot by locating the highest noise level. The device accuracy usually limits excavating to a minimum and thus provides resource-optimized network maintenance.

Our services at your disposal:

- Leakage detection on drinking water network systems and domestic installations

- Electro-acoustic listening

- Correlation measurements

- Search for even smallest leaks with hydrogen

- Search for metal and non-metal pipes

- Cable systems and drains

appointment coordinator

Mr. Udo Ochs

Phone: +49 (0) 7946 92100 12

E-Mail: